In the manufacture of equipments, such as heat exchangers, condensers, etc., it’s a matter of vital concernment that the tubes must be rolled at a controlled and uniform level to produce tight, leak proof tube-sheet joints, without inducing undesirable stresses and distortions on equipment structure. In order to serve this purpose, HANNA presents its rolling motors lines, both electrical and pneumatic with torque control. Rolling motors with torque control produce uniform tight joints, with both faster and more dependable results, even with inexperienced operators.

Rolling Motors

Torque Control Unit

The CT25M model Torque Control Unit is an electronic solid state, compact, lightweight unit, mounted on metallic box, developed to provide high reliability and long life service. The control unit fits all standard HANNA electric rolling motors, but requires specific calibration for each motor. The torque is controlled by means of monitoring the electric current drawn by the rolling motor. When this current equals a presetted value on dial, the power is cutted off from the rolling motor. After a few seconds the motor starts automatically at reverse direction to extract the tube expander.

Technical Features CT 25M – 127V

| Maximum motor power | 2.500W |

| Tension | 110VaC |

| Frequence | 60Hz |

| Weight | 2,0 Kg |

| Dimensions | 60 x 130 x 250 mm |

Características Técnicas CT 25M – 220V

|

Maximum motor power

|

2.500W |

| Tension | 22 0VaC |

| Frequence | 60Hz |

| Weight | 14,0 Kg |

| Dimensions | 200 x 300 x 400 mm |

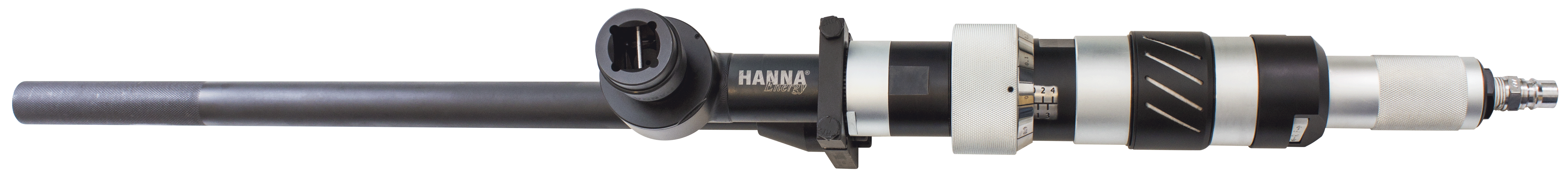

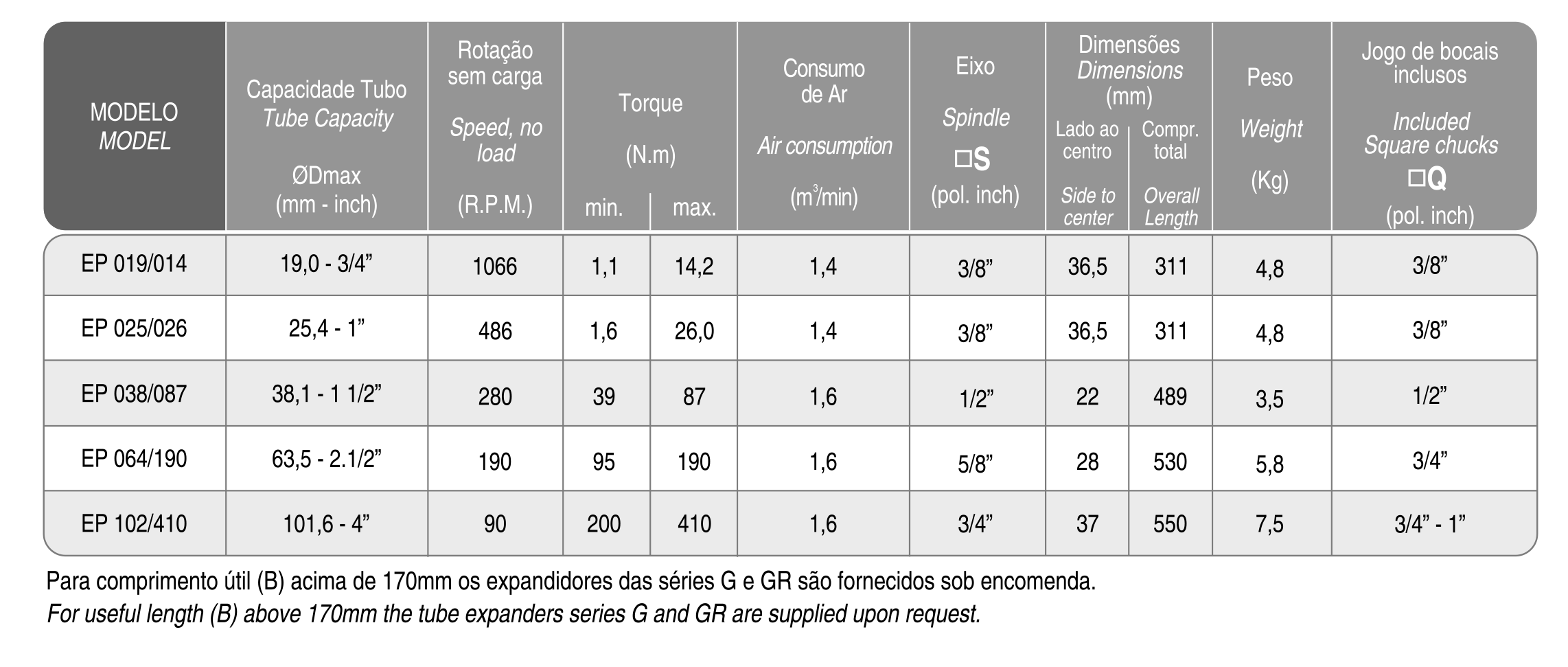

Air-driven Rolling Motors with Automatic Torque Control

The Air-driven Rolling Motors control expansion by accurate measurement of torque, assuring an uniform tube to tube expansion.

The air motors include a sensing cam that automatically stops expansion according to predetermined setting.

- Speed and torque at 90psi air pressure.

- ØDmax refers to outside tube diameter. Capacity may vary due to material, tube wall thickness and expansion length.